Customized Diffractive Optical Elements

For requirements beyond the off-the-shelf product range, we offer the development of customized Diffractive Optical Elements using different materials (polymers, fused silica) tailored to your application.

Problem Analysis & Feasibility Studies

The different types of DOEs (beam-splitters, pattern generators, kinoforms, beam shapers and gratings) utilize a microstructure surface relief profile for their optical function. Light transmitted by a DOE can be reshaped to almost any desired distribution, just by diffraction and the subsequent propagation. The DOE only encodes the shape of the desired intensity pattern, but maintains other parameters of the incident light source (e.g. beam size, divergence, polarization).

Due to their design flexibility, DOEs can have optical functions that can otherwise not be achieved at all, or only with complicated optical systems. Moreover, compared to refractive optical elements, DOEs are typically much thinner and lighter, making them an attractive replacement in a number of applications.

Essential Specification Parameters

Light Source

- Type (cw laser, pulsed laser, edge emitter/ VCSEL laser diodes, LED, other)

- Wavelength (center, bandwidth, tolerance, shift)

- Polarization

- Power/Energy (average and/or peak)

- Beam profile (diameter, divergence, M² beam quality parameter)

Optical Function

- Desired light field distribution (shape, uniformity, contrast,…)

- Target surface/object (inclination, shape, …) and sensor (CCD/CMOS/human eye/…)

- Field of view and working distance, or diffraction angles

Application

- Element form factor (size, shape)

- Element material (glass/polymer/…)

- Environmental conditions (temperature, humidity, exposure to UV radiation, …)

- Eye Safety requirements

- AR coating requirements

- Laser induced damage threshold (LIDT) requirements

- Packaging requirements

- Storage conditions

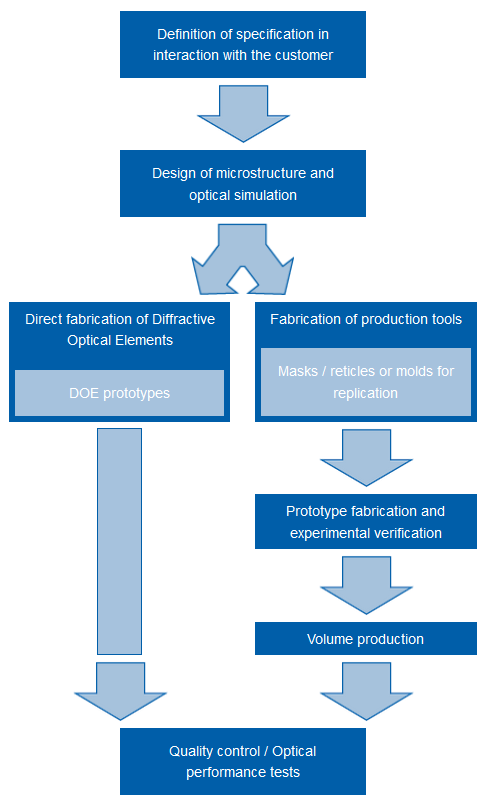

Process of DOE development

The required annual production volume and a price target are helpful in order to balance technical and economical requirements.

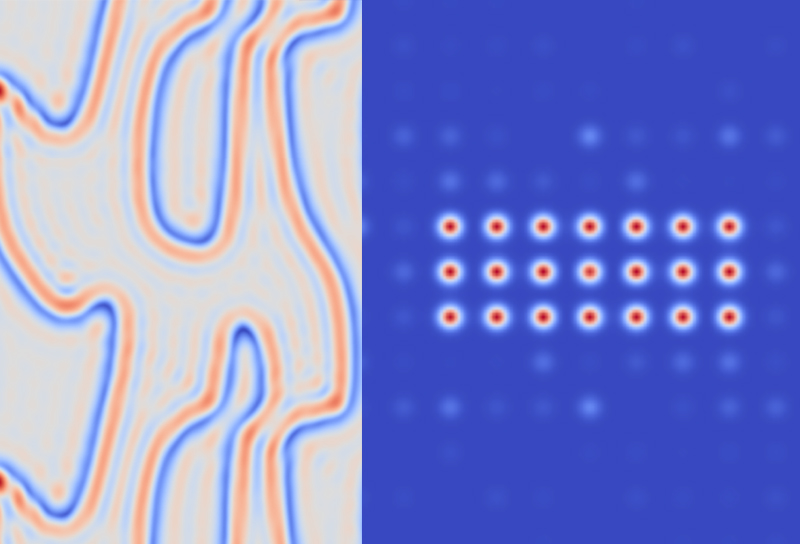

DOE Design & Simulation

HOLOEYE utilizes its steadily growing experience in the design and simulation of diffractive optical elements to offer its customers a competitive solution. Using in-house developed as well as commercially available state-of-the-art software tools and algorithms, appropriate simulation methods (paraxial or rigorous electromagnetic) are used for optimization of the DOE design.

Fabrication constraints are taken into account right from the start, and a tolerance analysis is performed whenever necessary. Also the alignment requirements of the DOE within the optical system are determined, so that the assembly procedure can be designed accordingly.

DOE Mastering and Tooling

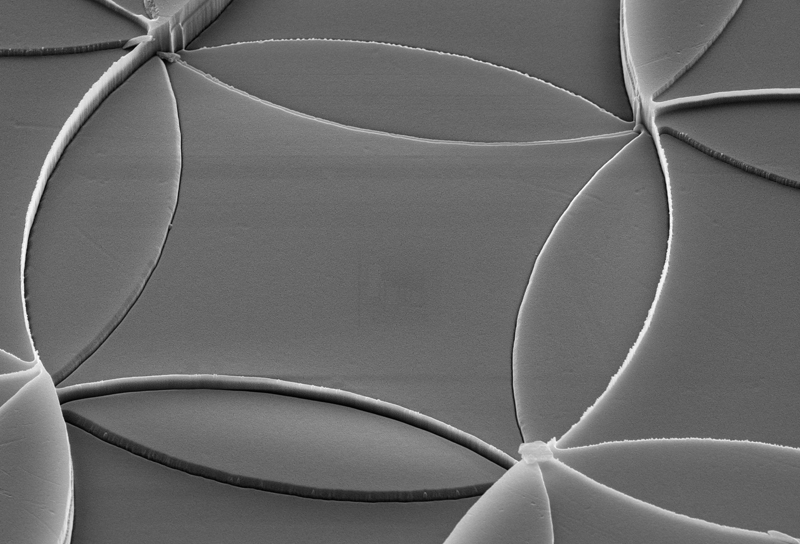

Direct write lithography processes are used to create either lithography masks or resist micro-relief profiles. Based on masks, micro-relief profiles are created by contact or projection lithography and subsequent etching processes like reactive ion etching to transfer the etch mask into the substrate.

The obtained micro-relief profiles serve as fused silica DOEs or templates for UV-curing based replication processes. Alternatively, electroplating can be used to create inverted resist profiles which are usable for embossing and molding processes of polymer materials.

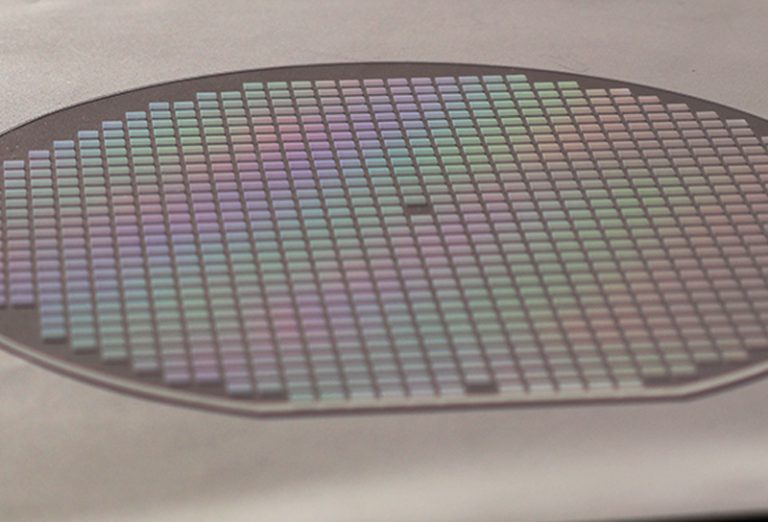

DOE Volume Fabrication

HOLOEYE offers diffractive elements fabricated by one of the following options:

- Bulk polymer elements, the substrate and a diffractive micro-relief surface are created by compression molding using materials like polycarbonate, PMMA, or Topas ®

- Acrylate-on-polymer elements, the diffractive layer is created by UV curing on a polymer substrate

- Acrylate-on-glass elements, the diffractive layer is created by UV curing on a glass substrate

- Bulk fused silica elements, the diffractive micro-relief surface is created by reactive ion etching.

The size and shape of the DOEs can be specified by the costumer. Fresnel-type surface reflections can be reduced by dielectric anti-reflective coatings, or by moth-eye micro-relief surface structures on the otherwise plain substrate surface.

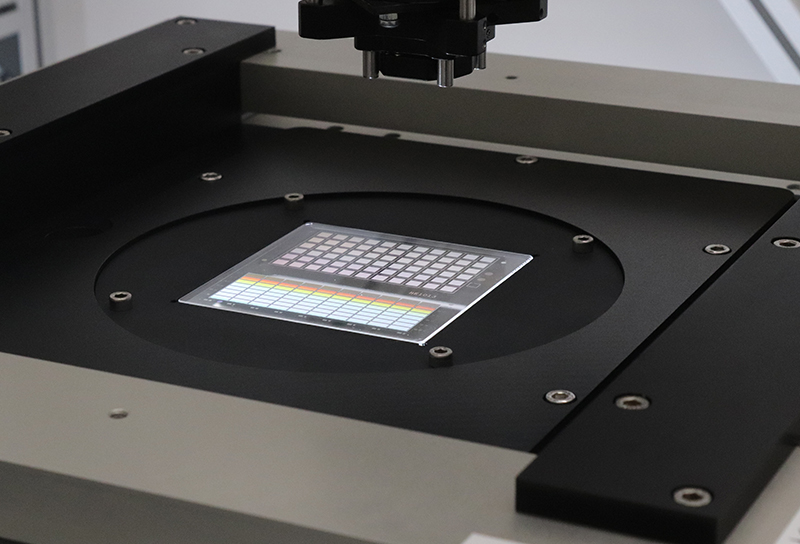

DOE Quality Assurance and Implementation Support

After fabrication, HOLOEYE will validate the compliance of the DOEs with the specification experimentally. For volume production of elements, optical key properties can be monitored using automated equipment.

When an integrated solution like a DOE-based laser projection module is required in your application, HOLOEYE can be part of a joint development effort involving vendors for those products.