Standard Diffractive Optical Elements

HOLOEYE offers a steadily growing range of affordable off-the-shelf standard Diffractive Optical Elements (DOE). These DOEs are either replicated using polymer materials or produced in glass materials.

Standard Polymer DOEs:

Our standard polymer Diffractive Optical Elements (DOEs) are crafted through surface replication using materials such as polycarbonate (PC) or polymethyl methacrylate (PMMA).

These elements, with a standard diameter of 8 mm and a thickness between 0.6mm and 1.2mm, are designed to seamlessly integrate into various standard laser modules.

For use in the optics lab, the DOEs are also available mounted in a 12.7 mm x 2.2 mm stainless steel adapter ring.

HOLOEYE’s standard DOEs empower laser module manufacturers and distributors to enhance their product lines with minimal investment. We welcome requests for size adaptations or other customizations, which will be provided based on a reasonable Non-Recurring Engineering (NRE) budget.

Standard Glass DOEs:

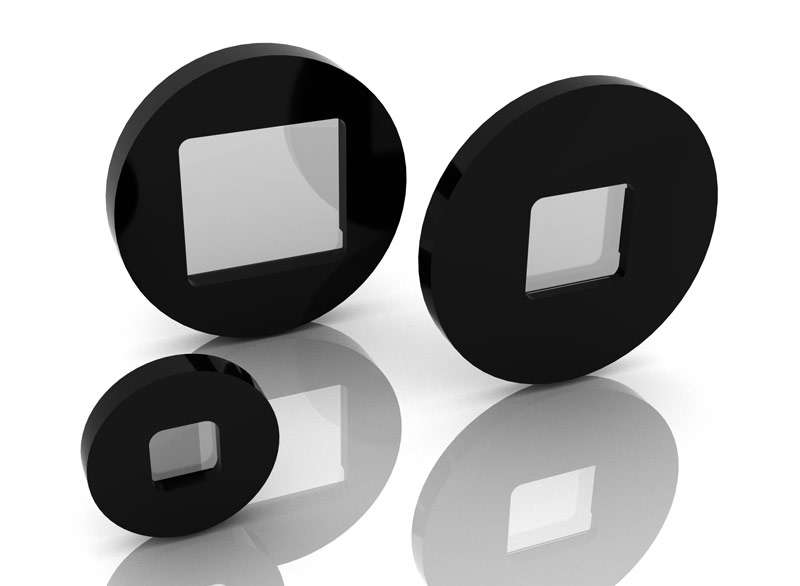

Our standard glass DOEs are made of fused silica glass by etching, or are replicated using acrylate on soda-lime glass substrates. In sample quantities, all size versions are available in circular holders for easy use with standard optics mounts.

Advantages of Glass DOEs Compared to Polymer-Based Diffractive Optical Elements:

- Durability: Glass DOEs are more rugged and scratch-resistant.

- Thermal Stability: They have lower thermal expansion coefficients (CTE).

- UV Resistance: They can withstand exposure to UV radiation without degradation, and can be used with UV lasers.

- Heat Resistance: They can endure significantly higher temperatures.

- Laser Power: They can handle significantly higher laser powers.

- AR Coating: They have anti-reflective coating on at least the plain surface side, several types on both surfaces

- Polarization-maintaining: They have negligible birefringence in the substrate.

Dependent on the type the glass DOEs are available in the following versions:

DOE Category II: Arylate-on-Soda-Lime glass: 5.2 x 4.7 mm

DOE Category III: Fused Silica: 5.0 x 5.75 mm

DOE Category IV: Fused Silica: 5.0 x 5.75 mm (multilevel)

DOE Category V: Fused Silica: 9.95 x 9.35 mm

DOE Category VI: Fused Silica: 9.95 x 9.35 mm (multilevel)

DOE Category VII: Fused Silica: 15.0 x 14.1 mm

DOE Category VIII: Fused Silica: 15.0 x 14.1 mm (multilevel)

In sample quantities, all versions are available in standard frames for use with standard laboratory mounts.

Ø 12.7 x 2 mm holder (for 5.2 x 4.7 mm / 5.0 x 5.75 mm DOEs)

Ø 25.0 x 2.2 mm holder (for 9.95 x 9.35 mm DOEs)

Ø 25.0 x 3.5 mm holder (for 15.0 x 14.1 mm DOEs)

Please note: If you click at any of the DOEs listed at the table below you get further information on each DOE. The images of the patterns are schematic drawings. In a real setup, higher diffraction orders can be visible, and the undiffracted order can appear as a bright spot in the center.

Material

Pattern Type

Wavelength Range

Full Pattern Angle

DOE#

Material

Description

Wavelength Range

Full Pattern Angle