New standard glass DOEs with different patterns:

- DE 805: 1:2 Beam Splitter, Full Pattern Angle: 0.25° @ 800 nm

- DE 806: 1:2 Beam Splitter, Full Pattern Angle: 0.5° @ 800 nm

- DE 807: 1:2 Beam Splitter, Full Pattern Angle: 1.0° @ 800 nm

- DE 808: 1:2 Beam Splitter, Full Pattern Angle: 2.0° @ 800 nm

- DE 809: 1:2 Beam Splitter, Full Pattern Angle: 4.5° @ 800 nm

- DE 810: 1:2 Beam Splitter, Full Pattern Angle: 10° @ 800 nm

- DE 811: 1:2 Beam Splitter, Full Pattern Angle: 2.0° @ 800 nm

- DE 812: 1:6 Beam Splitter, Full Pattern Angle: 2.5° @ 800 nm

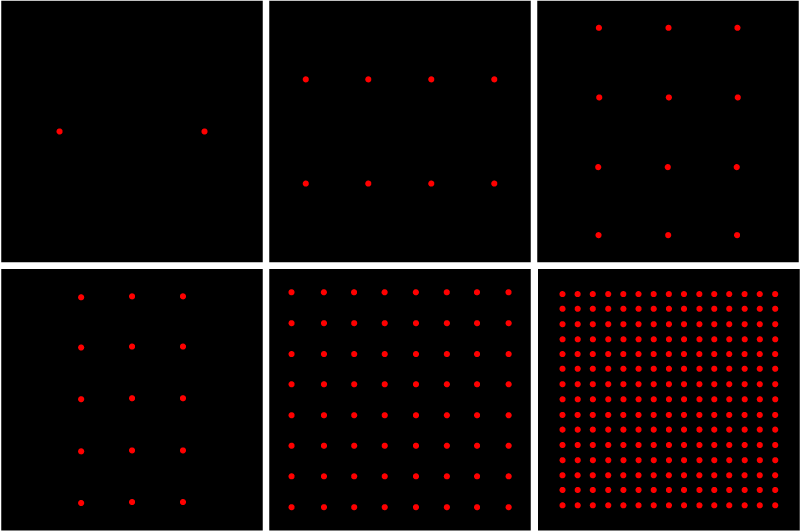

- DE 813: 4×2 Dot Matrix, Full Pattern Angle (diagonal): 2.4° @ 800 nm

- DE 814: 3×4 Dot Matrix, Full Pattern Angle (diagonal): 3.3° @ 800 nm

- DE 815: 3×5 Dot Matrix, Full Pattern Angle (diagonal): 3.3° @ 800 nm

- DE 816: 8×8 Dot Matrix, Full Pattern Angle (diagonal): 4.0° @ 800 nm

- DE 817: 15×15 Dot Matrix, Full Pattern Angle (diagonal): 5.9° @ 800 nm

These Fused Silica DOEs have a size of 9.95 x 9.35 mm at 0.67 mm thickness. In sample quantities, the DOEs are available in a circular metal frame for use with standard laboratory mounts.

Compared to DOEs made from polymer materials, the glass DOEs are more ruggedized. They are more scratch resistant, can withstand higher temperatures and higher laser powers, have lower thermal extension coefficients (CTE) and the fused silica DOEs can easily withstand exposure to UV radiation without degradation.

The range of available glass DOE will soon be extended to cover additional common laser wavelengths, like 532 nm and 1064 nm.